Surface

Perfectly reflecting the image.

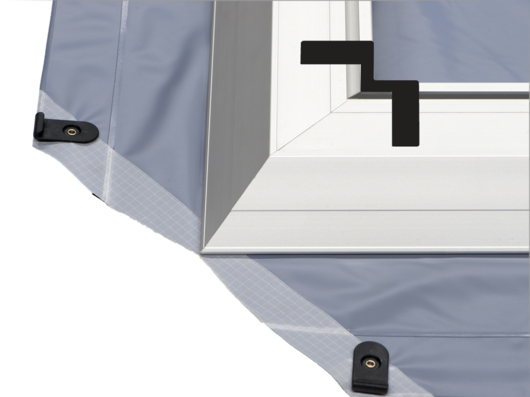

Fullwhite®’s vinyl surfaces can be stretched easily and attached to the frame’s rear side with hooks.

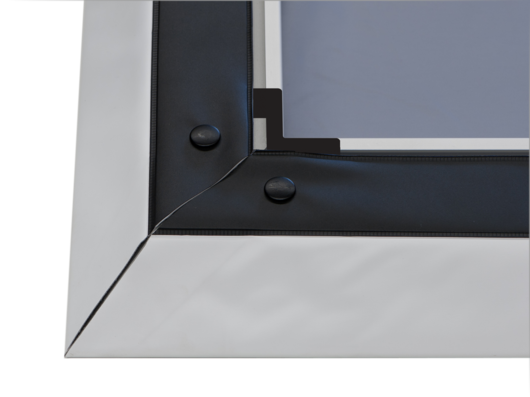

Manufactured to Quality

Especially developed. Top quality materials. Processed with care.

AV Stumpfl mobile projection screen surfaces have to meet strict requirements which we defined based on our 40 years of field experience. Beyond our special source materials we have developed our own machinery for PVC welding.

SEAMLESS OPTIC

Ultra Large Surface. Invisible Seams.

If projection screen height exceeds the material roll width multiple surface panels have to be welded together using our especially invented welding technique. For consistently perfect images even in near-viewing distance we recommend to flatten the necessary seams using our SeamlessOptic ™ technology.

OTHER MATERIALS

No standard is also a standard.

Fullwhite® technology can not only be used as a projection screen. By attaching printed materials Fullwhite® frames can be used in a number of different applications. It is possible to attach several Fullwhite® frames together to form multidimensional shapes. Among the applications of Fullwhite® are:

- Trade Show Booth

- Projection Cubes

- Conferencing or Stage Backgrounds

- Architectural Design Elements